Sundt switches from DJI to Skydio to enable a wider range of life-saving drone missions

Skydio 2 is changing the way many of our customers fly and conduct their business operations. Today I’m excited to share with you the story of Sundt Construction, a general contractor specializing in transportation, industrials, building, and renewables. After adopting Skydio in 2020, Sundt already projects a full phase-out of DJI drones and, by the end of 2021, Sundt will have transitioned its entire fleet over to Skydio autonomous drones.

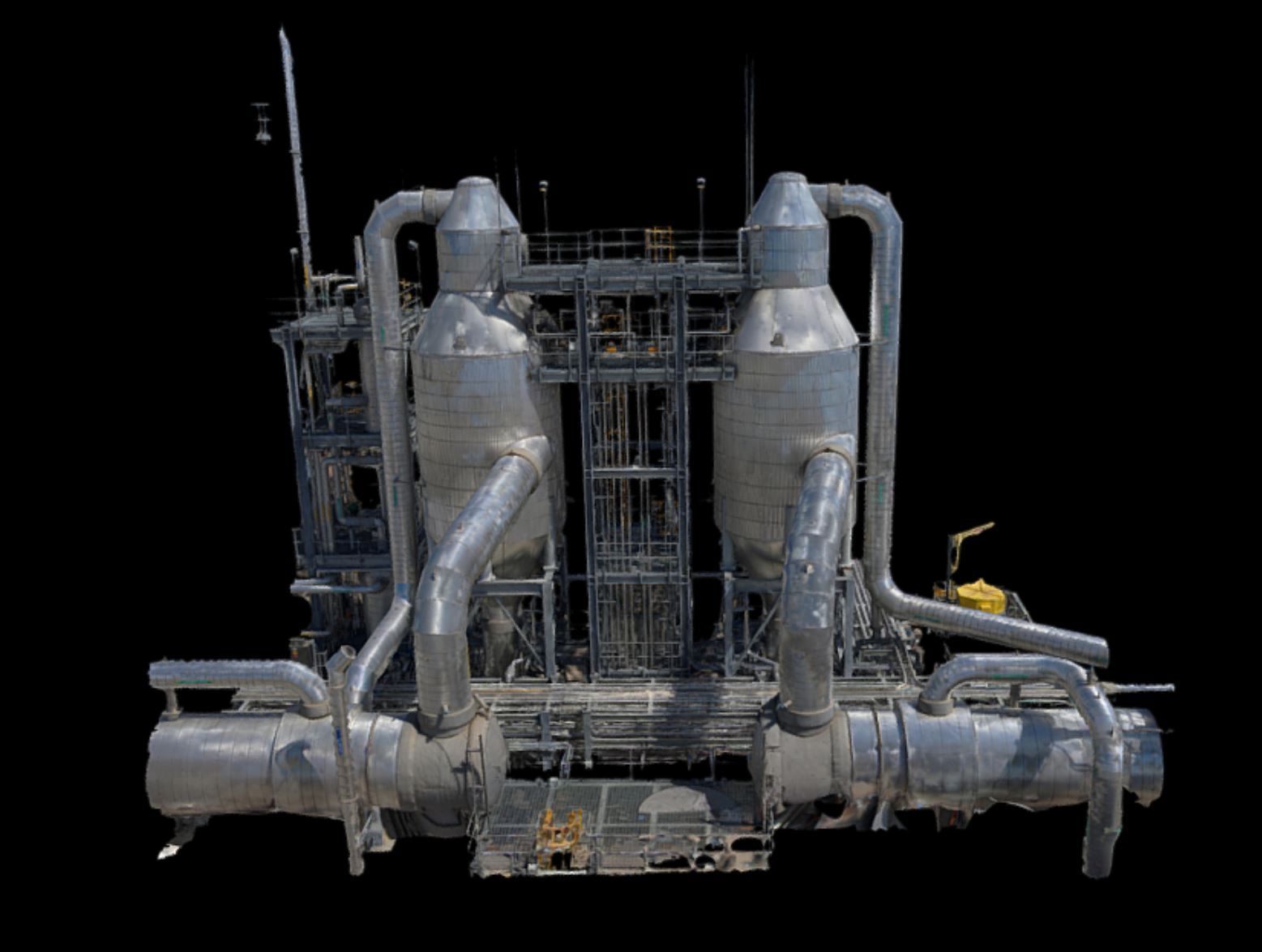

“ Sundt is using 3D Scan to create incredibly detailed and highly accurate models. We are using Skydio to replace traditional means of 3D modeling that use either manual drones or ground-based inspection, which are highly user-intensive and have high failure rates.

Challenge: ground-based inspection and manual drones were inefficient scan methods and put workers at risk

Manual DJI drones were hampering Sundt’s operations, despite having a focused team of full-time, Part 107 certified drone pilots. While a well trained pilot makes a huge difference, the shortcomings of manual drone technology fundamentally limit the effectiveness of even the most skilled operator. On obstacle-rich construction sites, this means compromising on data quality to lower the risk of expensive drone crashes. Additionally, Sundt’s existing method of scanning and mapping structures using ground-based inspection is a slow, manual process that puts workers in close proximity to extremely hazardous high-pressure, high-temperature systems.

Solution: Artificial intelligence & automation

Sundt has expanded their fleet to include 10 Skydio 2 Pro Kits and plans to fully phase out DJI drones by the end of 2021. Sundt Construction is able to capitalize on Skydio Autonomy, for 360º Obstacle Avoidance and reliable GPS-denied operations, as well as Skydio 3D Scan for elevated workflow automation. From BIM coordination to progress tracking, 3D Scan will make the process of capturing 3D models easier than ever before, reducing spending and the amount of time inspectors and team members need to spend in the field. With the Skydio 2, Sundt can fly with confidence through any job site, no matter the obstacles.

“ Sundt is using 3D Scan to create incredibly detailed and highly accurate models. We are using them to replace traditional means of 3D modeling with either manual drones or laser scanners.

Results: Skydio 3D Scan makes Sundt operations faster, better, and more efficient

Switching to Skydio has enabled Sundt to equip its growing team with AI-enabled tools that better serve enterprise customers. Their upgrade to autonomy has resulted in faster scanning, improved worker safety, and reduced pilot training requirements, and will make a variety of their operations, such as BIM coordination and progress tracking, more efficient.

- Up to 90% reduction in time to inspect

- Improved worker safety by switching from laser scanning to Skydio 3D Scan

- Reduced pilot training requirements by 50%

To learn how Sundt is generating this incredible value for their own operations and their customers, please check out the full case study, available for download on Skydio.com, or check out the 3D Model they scanned on our company Sketchfab here. And to hear from Sundt directly, please check out Virtual Construction Engineer Dean Miller’s appearance on our Recent Webinar, Autonomous Drones Ready for Work: Skydio Solutions for Construction.