Skydio 3D Scan Example - Corsair Jet

The drive toward the general availability of Skydio 3D Scan continues, and spectacular models keep rolling in as we and our beta customers perform exhaustive testing to make sure the product is reliable and effective enough to deliver on the promise of automated inspection of a wide range of structures. As a reminder, 3D Scan is the first-of-its-kind adaptive scanning software built on top of Skydio Autonomy. 3D Scan automates data capture of any scene with comprehensive coverage and ultra-high resolution so that crews can perform higher quality inspections in less time and with minimal pilot training.

Last week, we shared our first-ever public 3D Model generated by 3D Scan, a spectacular rendering of a Crane Mast. Today’s model (browse it in Sketchfab!) is of an abandoned A-7 Corsair II, an American fighter jet from the 1960s. While this was an abandoned site in drone-friendly airspace, using unmanned aircraft for commercial inspection of manned aircraft is an exciting opportunity. These inspections must be performed from annually to as frequently as every 100 flight hours, depending on the model and use-case of the aircraft. Drone technology promises aviation units, post-incident investigators, and inspection crews the opportunity to rapidly pore over every surface of an aircraft, and generate decision-quality data with ease.

The abandoned Corsair fuselage, with a person for scale. This is an image taken from the drone (not to be confused with the 3D Model screenshots below).

However, inspecting the metallic fuselage of an aircraft is challenging with a manual drone. Manual drones have untrustworthy obstacle avoidance and cannot fly up close or in overhung areas like below wings, engines, or cargo holds, where GPS fails and magnetometers are unreliable due to metal structures. So, to inspect a jet, a typical manual drone inspector would have to maintain a long standoff distance from the subject, relying on an expensive and delicate zoom camera to generate precision imagery from a high-altitude grid pattern. It presents even more challenges if the pilot is trying to capture data of an aircraft sitting inside a hangar, where there is no GPS, and obstacles abound.

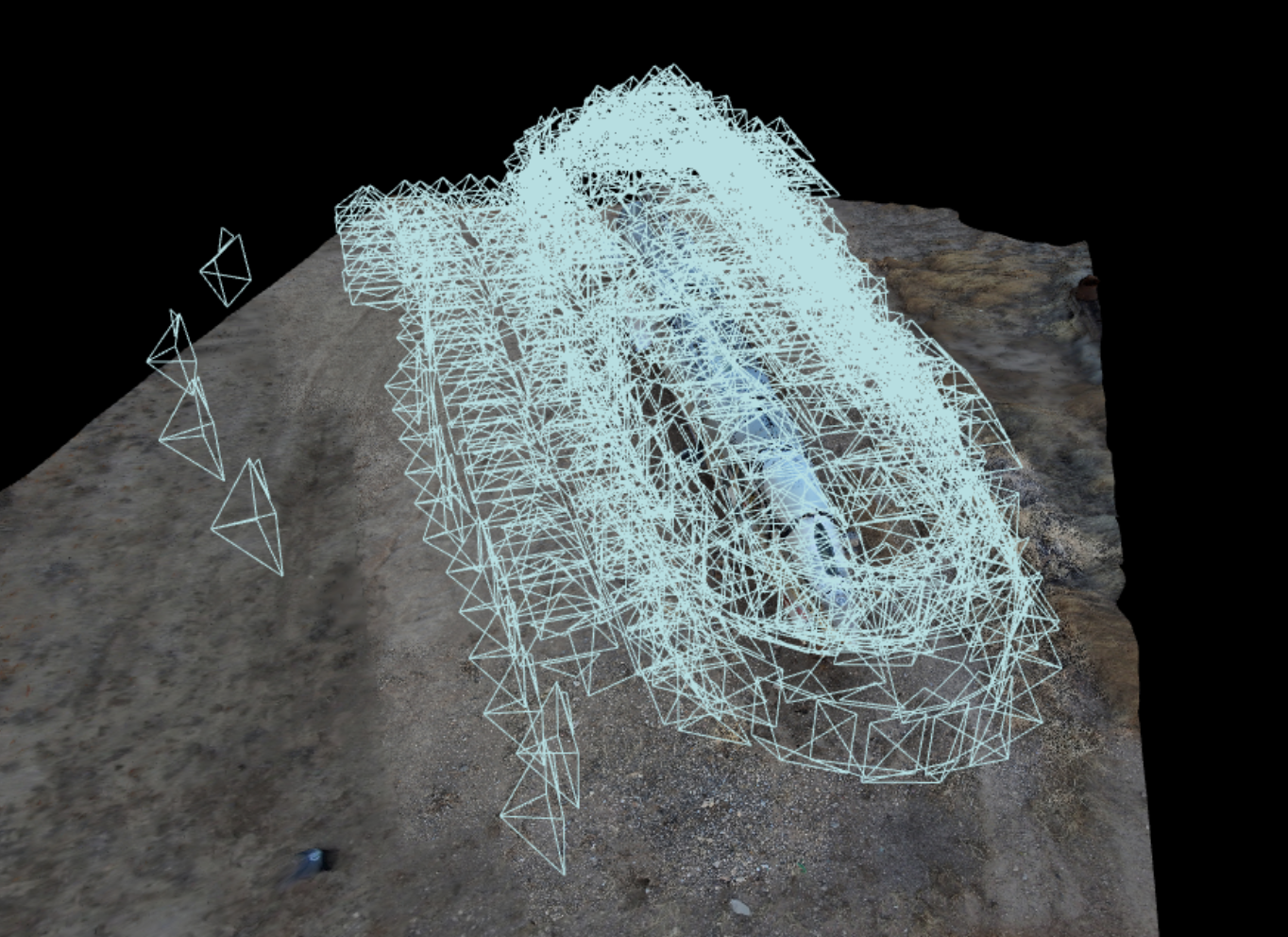

The metallic structure of a jet fuselage is difficult for a manual drone to navigate near, requiring long standoff distances and expensive hardware to compensate for conservative flight patterns. This is a screenshot from the 3D model.

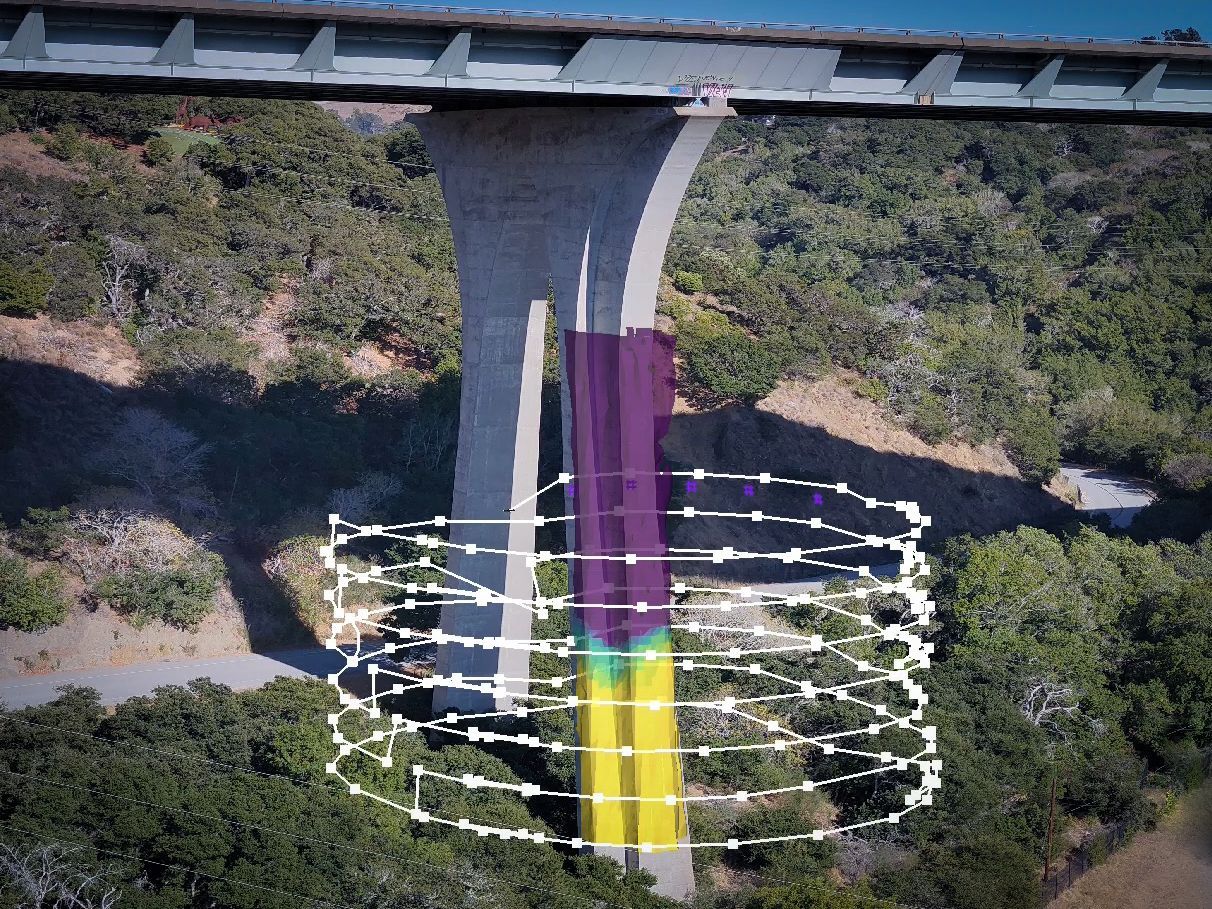

Not so with Skydio 3D Scan. Skydio’s Adaptive Mapping algorithms help the drone iteratively design a structure-specific 3D Scanning path, and follow it with full obstacle avoidance engaged. The Skydio vehicle autonomously explores and models the structure as it flies, and then automatically executes an image capture plan that provides efficient and complete coverage. As a result, the drone can capture imagery up close, from multiple angles, of every point in the pilot-specified scan volume. On this structure, it is clear how the drone designs a unique pattern for the subject at hand, and generates a spectacular 3D model. The observant aircraft inspector will note that the flight pattern closely hugs the aircraft, meaning jets can now be inspected in their own hangars, without needing to be transported to wide-open areas first.

With its Adaptive Scanning algorithms, Skydio autonomously discovers structures while in flight and generates optimized flight patterns that provide the best possible output.

This model was built with DroneDeploy. As you may know, Skydio has an SDK partnership with DroneDeploy, so that DroneDeploy customers can use Skydio drones as part of their typical inspection workflows. Skydio 3D Scan will take Skydio + DroneDeploy operations to the next level. Soon, pilots will be able to use Skydio 3D Scan in the Skydio Enterprise Application and export their photos to DroneDeploy to produce a spectacular new level of model quality. We are excited to keep working with our friends at DroneDeploy to help our shared customers take their inspection programs to new heights.

One of nearly 600 photos to comprise the scan, this image shows the benefits of being able to fly up close - capturing incredible detail at low angles inaccessible to any camera flying at the long standoff distances required by manual drones.

Additional capture details are below. To learn how you can apply this incredible new technology to your inspection operations, please do not hesitate to contact us.

Capture

- Platform: Skydio 2

- Date: Feb 16, 2020

- Distance: 10 ft

- GSD: 1.25 mm

- Overlap / Sidelap: 80 / 70%

- Photos: 595

- Flight Time: 30 minutes (1.5 batteries)

Structure Dimensions: 46ft by 16ft